Passionate and committed, the Percipio Robotics team develops, qualifies and implements the robotic solutions you need to grip and manipulate your micro components with the highest precision.

We support you, through a structured approach, from the definition of your needs to the delivery of a robust and qualified industrial solution.

Our robotic development platforms, our process solutions, and our software are at your service to define together the technical solutions that will meet your expectations.

In addition, our digital approach for the configuration of our devices allows you to use the full potential of Industry 4.0 tools, from process development to performance optimization and maintenance of your solutions.

Our resources at the service of your processes:

La miniaturisation est omniprésente dans les objets de notre quotidien.

Dans nos appareils portables, nos solutions médicales, l’intégration des solutions du futur pose des challenges que nous pouvons relever.

Le marché de la miniaturisation est en pleine expansion : les technologies MEMS, photonique, et médicales sont promises à des taux de croissance importants et des évolutions rapides sur les 10 prochaines années, amenant de nouveaux défis techniques.

Nos solutions d’assemblage offrent le meilleur de la précision et sont basées sur l’utilisation intense de solutions numériques (vision industrielle, programmation, paramétrage) pour optimiser leur souplesse, afin de permettre à l’outil de suivre les évolutions des produits.

Par l’utilisation de la robotique adaptative, nous vous apportons de la performance industrielle, et des moyens concrets de répondre aux besoins de réindustrialisation.

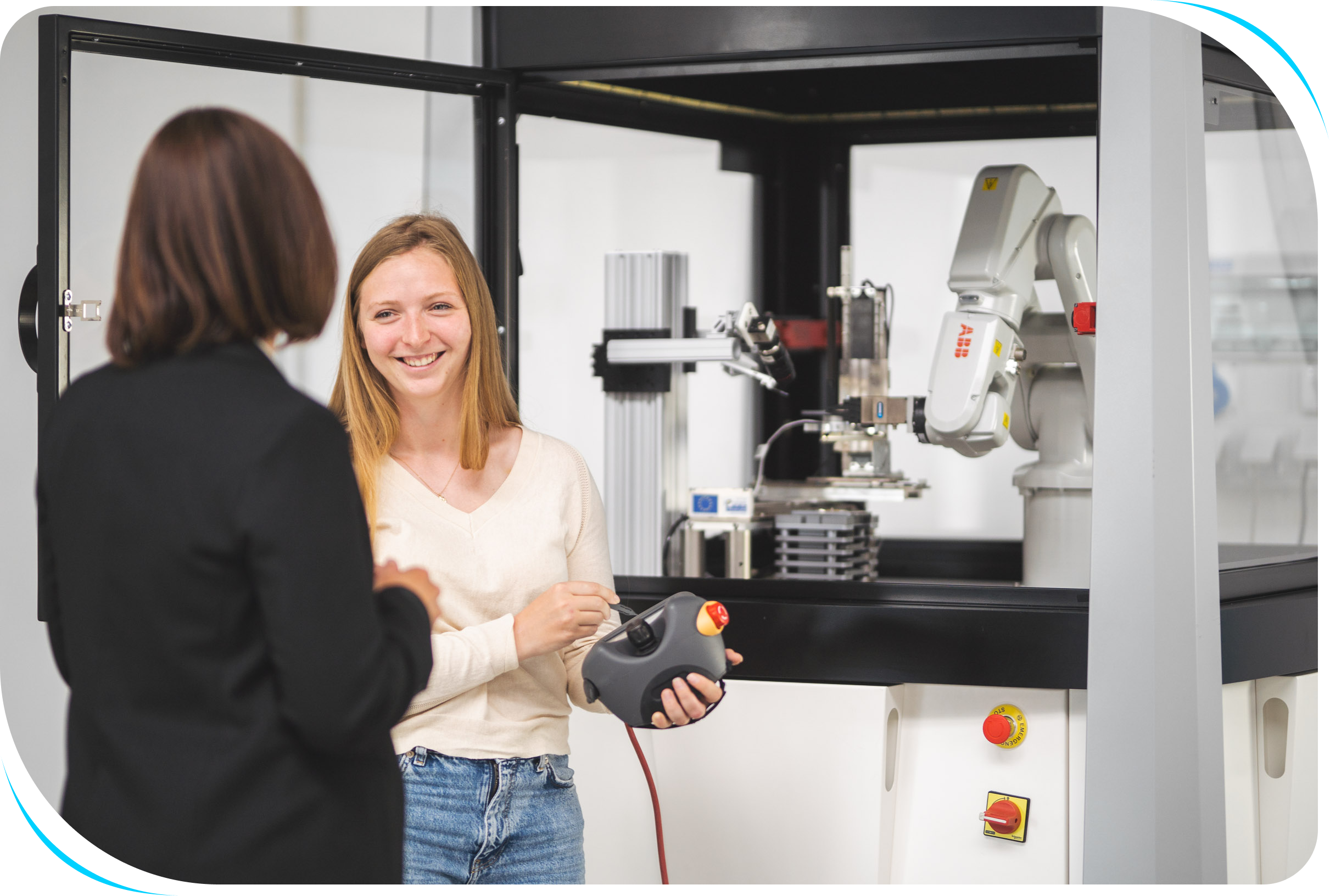

Cobotics refers to a device synonymous with modularity and evolution, where the machine plays a synergistic role with the human.

Our platforms are smartly designed with a strong evolutionary capacity: it is easy and quick to modify its embedded equipment (dispensers, grippers, cross-linking solutions…).

➔ The prototyping and pre-series assembly phases are therefore perfectly adapted to the implementation of cobotic tools (à faire apparaitre en bleu)

Faster and cheaper to set up than automatic machines, cobotic tools are full of advantages. The performance of the robot is combined with the intelligence of the operator, to bring a control of the precision assembly process at a reasonable cost.

Moreover, our cobotic tools are equipped with the same software as our automatic systems: they allow a progressive automation of the assembly process to gain time or precision on the most coherent phases, by adapting to the increase in production volume.

Flexibility

Speed of developpement

Economic gain

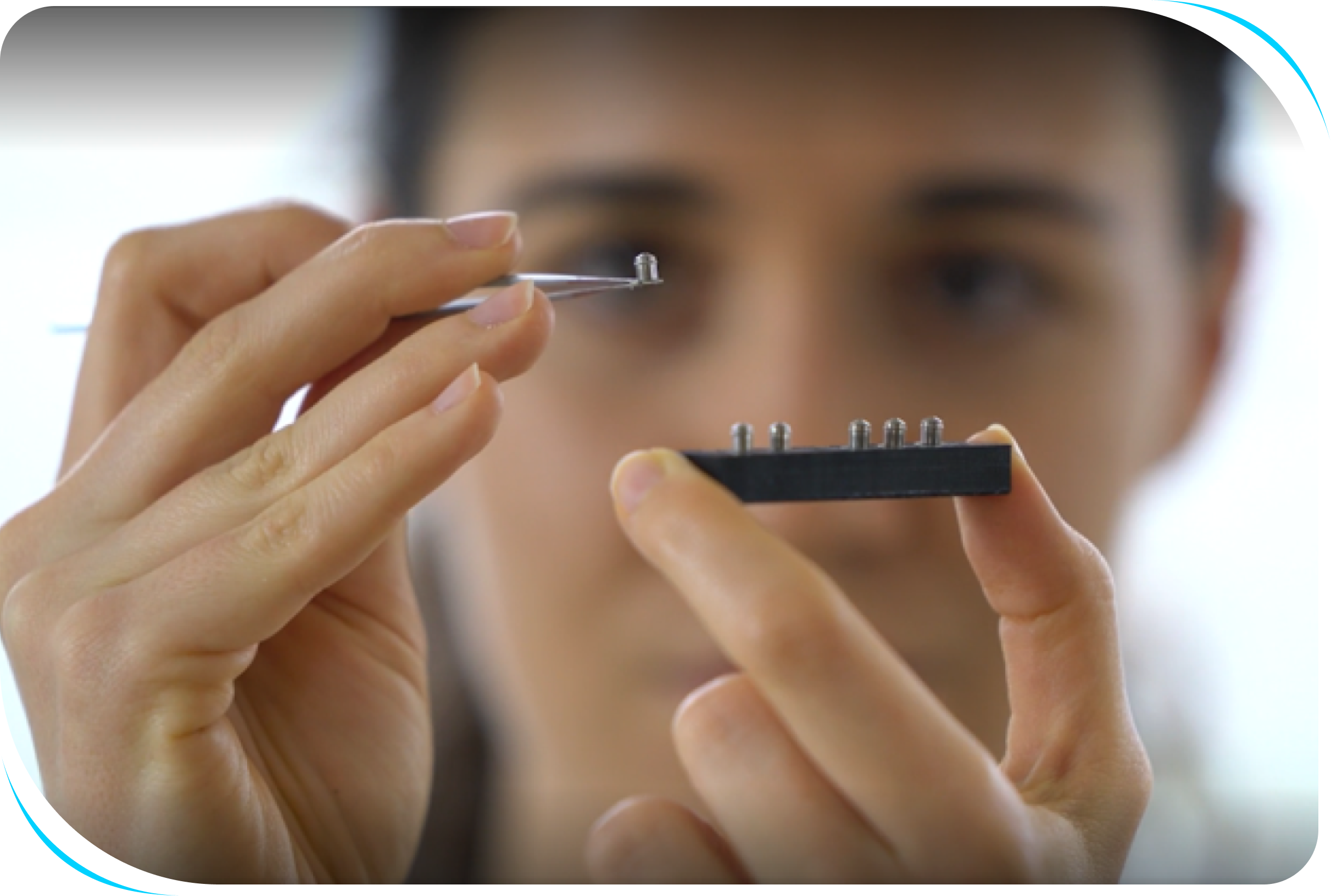

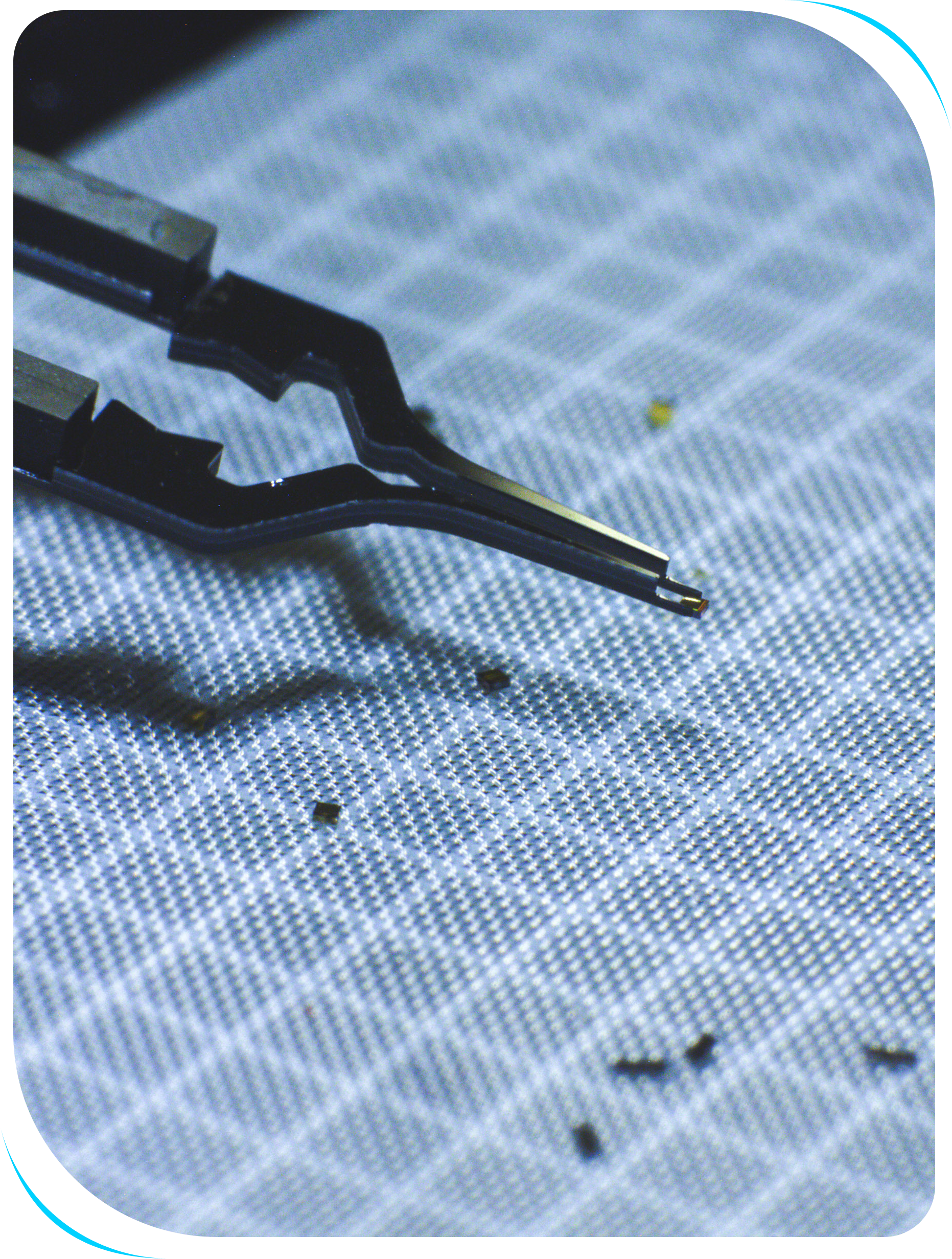

La micro-préhension est une discipline délicate, qui nécessite de comprendre les produits eux-mêmes de façon à pouvoir s’adapter à leurs spécificités et ainsi révolutionner les modes d’assemblage.

Percipio Robotics a conçu grâce à son expertise du micro-monde, des produits de préhension performants, dédiés au micron, adaptables et validés sur de nombreux cas applicatifs.

Réaliser des systèmes précis et robustes est un défi qui nécessite d’interfacer le meilleur des éléments robotiques (préhenseurs, axes, dispensers…) avec un processus de vision industrielle haute définition.

L’ensemble est contrôlé par nos logiciels propriétaires, modulaires et spécifiquement dédiés au micro-assemblage.

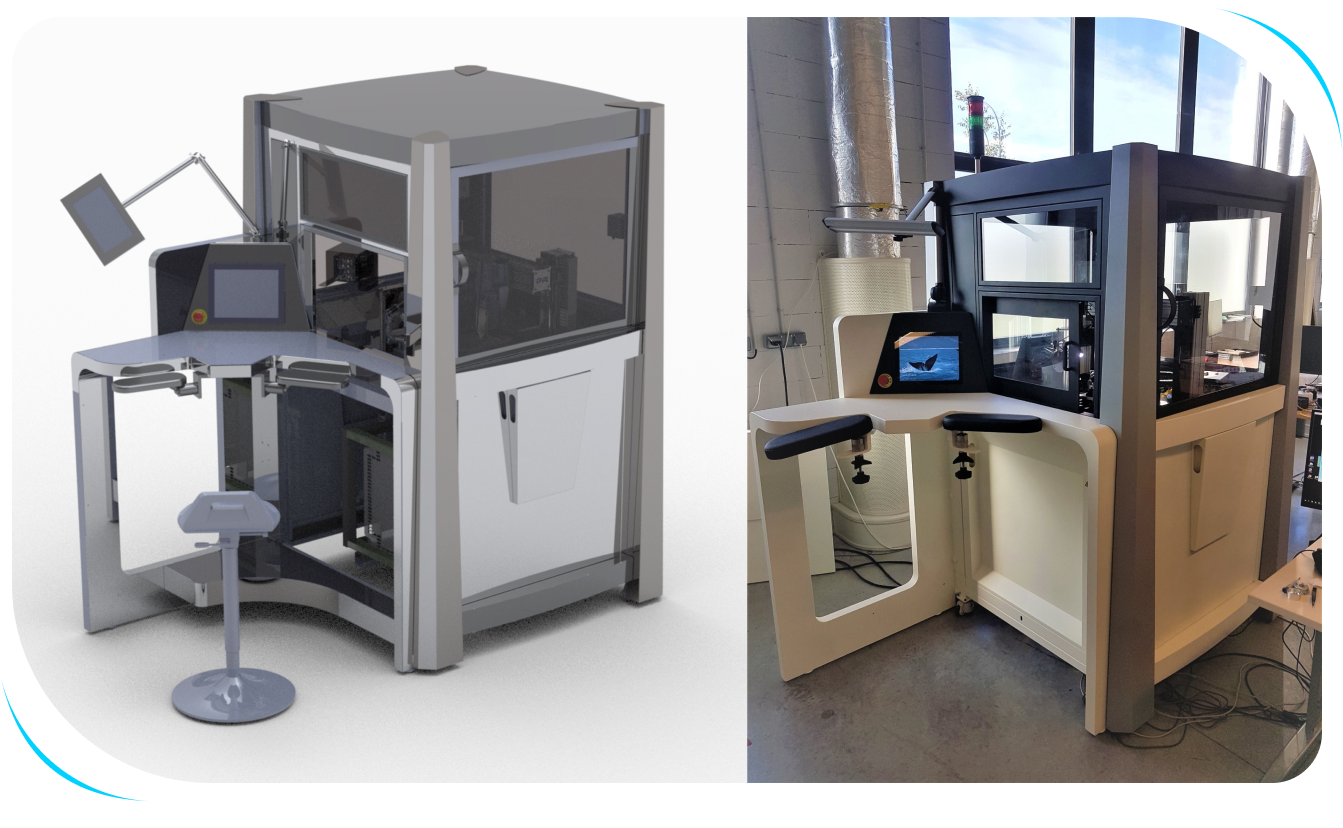

The Chronogrip is our standard cobotic tool.

We adapt it and use it on a daily basis for our feasibility studies.

As part of our growth, we are currently developing new platforms, even more modular, with user-friendly interfaces to support our future developments and yours.

To interface with the machine, we offer a multitude of possibilities: Joystick, game controller, haptic feedback controller or HMI on touch screen, everything is possible to adapt to the process and user preferences.

To interface with the machine, we offer a multitude of possibilities:

Joystick, game controller, haptic feedback controller or even HMI on touch screen, everything is possible to adapt to the process and user preferences.

Efficient in terms of production, automatic machines are so autonomous that human intervention is discreet, without impacting the performance of robotics

Percipio Robotics machines are based on robotic systems – so they are reprogrammable, flexible and adaptable.

They can be adapted to the diversity of your products and their evolution, infinitely easier than a classic special machine.

Their digital control mode allows them to be ideally integrated into a controlled and mastered production system:

The data thus generated can be used for :

– production control, assembly conformity or performance analysis of the finished product.

We can consider all types of interfacing with upstream and downstream production data (management of batch numbers with identification by QR code, NFC Tag, file exchanges, etc.) to enrich your production analyses.

In addition, our customer support policy allows for optimal responsiveness:

We continue to develop additional troubleshooting solutions to support our customers in the maintenance of their devices even more effectively.

Efficiency

Reliability

Flexibility

Scalability

4.0 connectivity

Speed

Remote access

Easy maintenance